Recognizing the Significance of Membrane Switch in Modern Electronics and Their Applications

Membrane switches over act as a vital component in modern electronics, providing an efficient user interface for user communication. Their lightweight and customizable nature makes them suitable for a variety of applications throughout varied sectors. Comprehending their vital components and advantages can supply insights into their expanding importance. As modern technology proceeds to breakthrough, the advancement of Membrane changes questions concerning their future applications and style innovations. What exists in advance in this dynamic field?

What Are Membrane Switches?

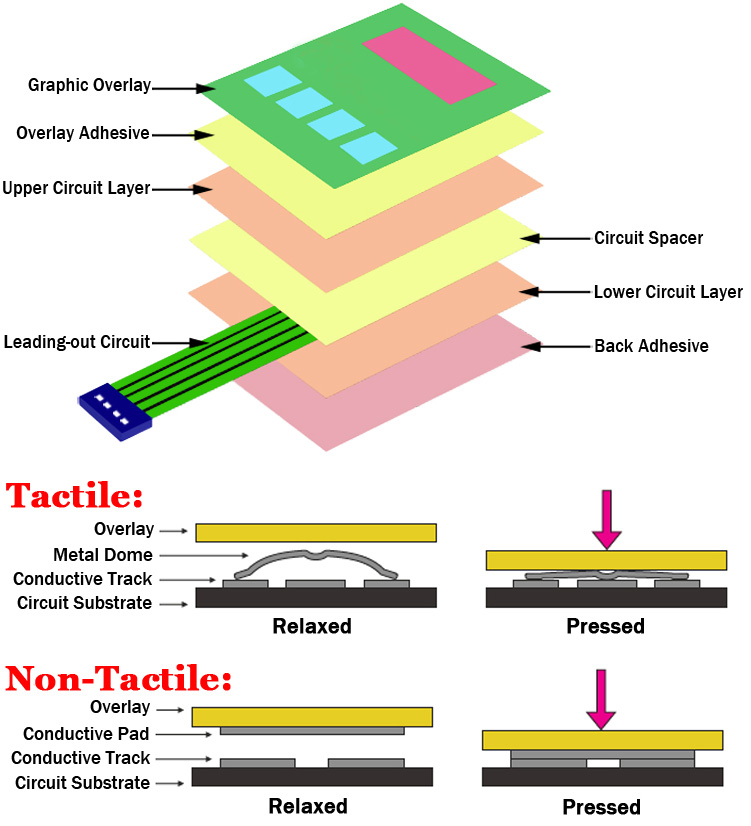

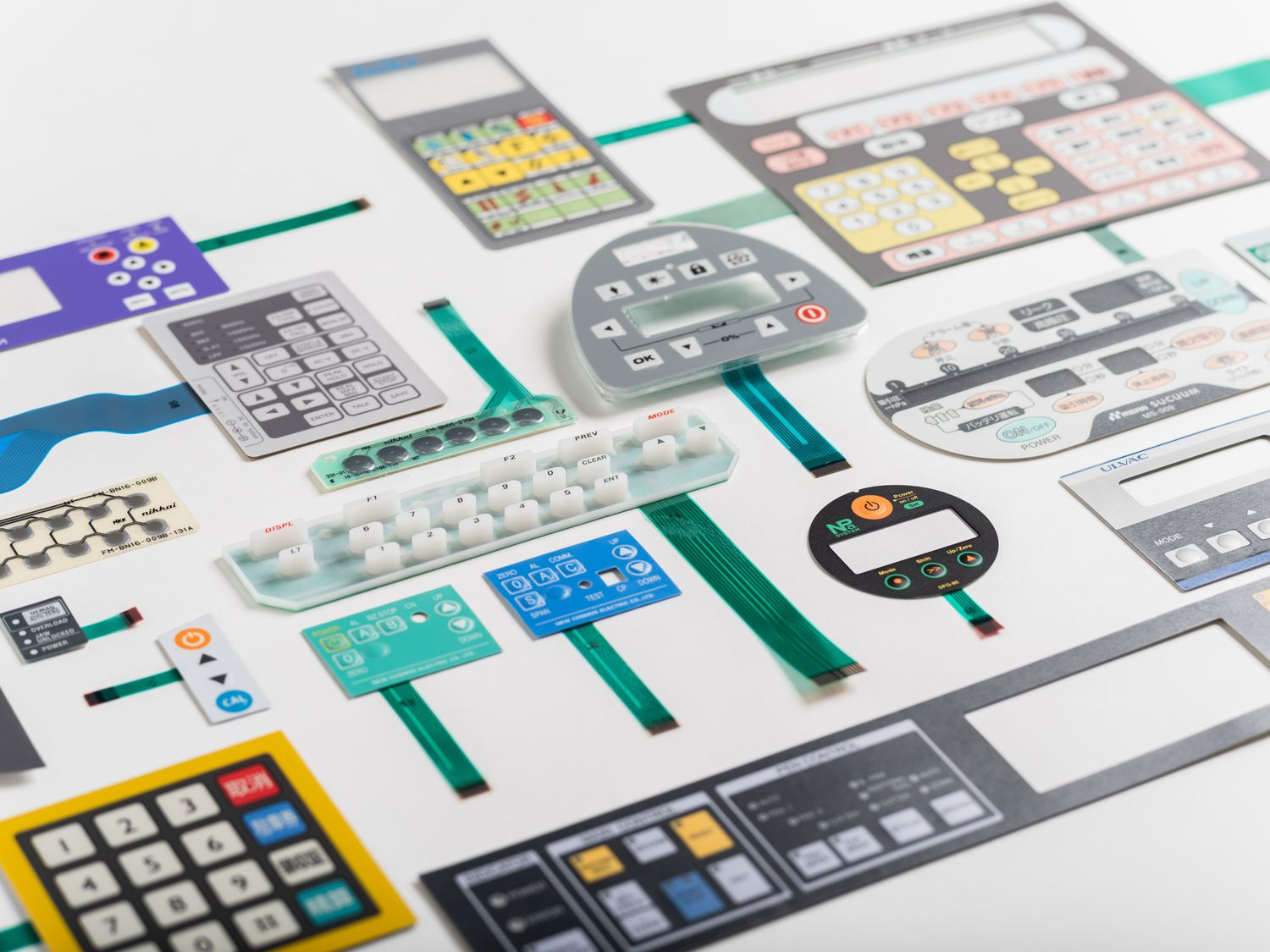

Membrane switches are crucial parts in modern electronics, working as interface that help with communication between individuals and tools. These buttons include numerous layers, including a graphic overlay, a sticky layer, and a circuit layer, every one of which collaborate to develop a useful and durable interface. The design permits a level, low-profile solution that can be personalized pertaining to dimension, shape, and visual look, making them ideal for different applications, from consumer electronic devices to clinical gadgets. The responsive feedback supplied by Membrane changes enhances customer experience, while their resistance to dust and wetness makes them ideal for challenging atmospheres. Membrane buttons can include features such as backlighting and published graphics, further broadening their functionality. Their adaptability and toughness make them a favored selection in industries where integrity and simplicity of usage are paramount, eventually adding to the seamless procedure of modern digital tools.

Secret Parts of Membrane Switches Over

While numerous elements add to the performance of a membrane layer switch, three main layers play substantial duties in its design and operation. The top layer, commonly made from a long lasting polymer, works as the user interface for user communication, usually featuring published icons and graphics. Underneath this is the spacer layer, which keeps the necessary range between the leading layer and the circuit layer. This spacer layer assurances that the switch triggers only when pushed, stopping unexpected inputs. The circuit layer consists of conductive traces that finish the electric circuit when the top layer is dispirited. These traces can be made from different materials, consisting of copper or silver. Together, these parts develop a reputable and durable gadget that is portable and versatile, ideal for a wide variety of electronic applications, from household appliances to medical tools. Comprehending these crucial elements is vital for valuing the total functionality of Membrane buttons.

Advantages of Using Membrane Switches

Membrane Switch Manufacturing Process

Comprehending the Membrane switch production procedure exposes the complex actions associated with creating these crucial components. The process commonly begins with the design stage, where requirements and designs are developed using specialized software. Following this, the graphic overlay is printed on a versatile substrate, usually using high-resolution printing strategies to guarantee clearness and precision.Next, the sticky layers are applied, which offer to bond the different parts together. The circuit layers, made from conductive inks or materials, are then published onto a separate substratum. These layers are carefully aligned and laminated flooring to develop a practical switch.After setting up, the switches go through evaluating to verify capability and durability. Quality control steps are carried out throughout the procedure to determine and fix any problems. The completed Membrane buttons are packaged and prepared for circulation, ready to meet the needs of modern-day electronic applications.

Applications of Membrane Switches Over in Various Industries

Membrane switches are progressively made use of throughout various industries, specifically in medical equipment and customer electronics. In the clinical area, they offer reliable control user interfaces for tools that need specific procedure. In a similar way, in consumer electronic devices, these buttons boost user interaction by using smooth and receptive interfaces.

Medical Tools Control

Countless contemporary medical devices make use of Membrane buttons for structured procedure and enhanced individual communication. These switches give a trustworthy, durable user interface for a variety of applications, including analysis equipment, client monitoring systems, and medical tools. Their personalized designs enable specific formats that can fit the special requirements of health care professionals, making Web Site sure user-friendly navigation and efficient accessibility to necessary features. In addition, Membrane switches are immune to pollutants, making them suitable for sterile atmospheres. The tactile responses they use can improve user self-confidence, minimizing the danger of errors during important medical treatments. On the whole, the integration of Membrane buttons in clinical tools significantly adds to boosted functional efficiency and person security in healthcare settings.

Customer Electronic Devices Interfaces

In the domain name of customer electronic devices, Membrane switches play a critical function in enhancing customer interfaces throughout a wide variety of tools. These switches are indispensable to products such as remote controls, microwaves, and gaming consoles, offering a straightforward and effective interface. Their design permits for a smooth assimilation of graphics and performance, allowing suppliers to create streamlined, modern-day appearances without compromising use. Membrane buttons are also known for their longevity, usually enduring comprehensive use and exposure to different environmental problems. In addition, they can integrate features like backlighting and tactile feedback, further enhancing the customer experience. As customer needs for sophisticated yet user-friendly interfaces grow, Membrane changes proceed to be a crucial component in progressing digital device performance.

Design Factors To Consider for Membrane Switches

Creating reliable Membrane switches over calls for cautious focus to various factors that affect both capability and user experience. One important factor to consider is the option of materials, as they can impact sturdiness, responsive responses, and visual appeal. Choosing an ideal adhesive is necessary for assuring lasting attachment and resistance to ecological factors.In addition, the layout and design of the button have to suit customer interaction, with button dimensions and spacing enhanced for convenience of use. The consolidation of graphics and labeling need to focus on clearness and exposure under different lights conditions.Consideration of electrical attributes, such as actuation force and button sensitivity, will certainly improve the responsiveness of the Membrane switch. The design should fit manufacturing processes to guarantee cost-effectiveness and prompt production. Overall, a well-thought-out style improves both the performance and the customer experience of Membrane switches in modern-day electronic devices.

Future Fads in Membrane Switch Innovation

As modern technology remains to advance, Membrane switches are positioned to integrate new innovations that will certainly improve their functionality and application in different fields. One substantial trend is the consolidation of adaptable and long lasting products, which will certainly boost the life-span and straight from the source reliability of these switches. Boosted surface area appearances and personalized graphics are additionally prepared for, permitting more instinctive customer interfaces.Moreover, the combination of wise innovation, such as touch-sensitive surfaces and haptic feedback, is anticipated to improve individual communication, making Membrane switches a lot more interesting and responsive. In addition, developments in published electronics will certainly allow extra intricate wiring within thinner accounts, better increasing design possibilities.Sustainability will certainly also play an essential duty in future advancements, as makers check out green products and manufacturing processes. In general, these trends will assure that Membrane switches over continue to be essential and appropriate in an interconnected and significantly digital globe.

Frequently Asked Questions

How Do Membrane Switches Over Compare to Traditional Mechanical Buttons?

Membrane switches over offer advantages over typical mechanical see this here buttons, including decreased dimension, lighter weight, and enhanced resilience. They normally give a sealed surface area, boosting resistance to dirt and dampness, making them suitable for diverse applications.

What Products Are Generally Used in Membrane Switch Construction?

Can Membrane Switches Over Withstand Extreme Environmental Issues?

Membrane switches can stand up to extreme ecological conditions, depending upon their design and products. Top notch constructions typically include toughness against temperature changes, humidity, and direct exposure to chemicals, making them ideal for different demanding applications throughout markets.

For How Long Do Membrane Switches Over Normally Last Prior To Failure?

Membrane switches typically display a lifespan varying from 1 to 10 million actuations, depending upon aspects such as usage frequency, environmental conditions, and manufacturing high quality. Normal upkeep can prolong their longevity and functional reliability substantially.

Are Membrane Switches Adjustable for Particular Applications?

Membrane buttons are certainly adjustable for particular applications. They can be tailored in functionality, layout, and dimension, enabling suppliers to fulfill distinct customer needs and improve item appearances while maintaining functional performance and longevity. Membrane switches are vital elements in modern-day electronic devices, offering as customer interfaces that help with communication in between users and gadgets. The tactile responses offered by Membrane switches over enhances individual experience, while their resistance to dust and wetness makes them excellent for testing atmospheres. The consolidation of graphics and labeling need to prioritize quality and visibility under numerous illumination conditions.Consideration of electrical attributes, such as actuation force and button sensitivity, will boost the responsiveness of the Membrane switch. Enhanced surface area structures and customizable graphics are also anticipated, enabling for even more user-friendly user interfaces.Moreover, the integration of smart modern technology, such as touch-sensitive surfaces and haptic feedback, is expected to boost user interaction, making Membrane changes extra interesting and receptive. Membrane changes offer advantages over typical mechanical buttons, consisting of lowered size, lighter weight, and improved longevity.